研究背景

作为一种新型建筑结构形式,在住宅建筑中展现出广阔的应用前景。目前,国内外学者已对钢筋混凝土柱、钢管混凝土柱及纯钢异形柱等不规则截面柱的抗震与开展了系统研究。相较而言,混凝土包裹型钢柱(Concrete Encased Steel, CES)因具有更高含钢率和较低配筋率的特点,更适用于装配式钢结构建筑体系。

课题组前期试验表明,异形CES柱因混凝土保护层较薄,易出现早期开裂与保护层剥落现象,这不仅限制了型钢与混凝土的组合作用效果,还可能引发钢筋锈蚀等耐久性问题。现有关于混凝土剥落控制的研究多集中于规则截面柱,对异形截面柱的关注相对不足。鉴于异形截面应力分布的复杂性,开展针对薄混凝土保护层异形CES柱裂缝控制的试验研究显得尤为必要。

为解决薄混凝土保护层异形CES柱混凝土过早开裂和剥落的问题,本文将钢纤维混凝土应用于十字形CES短柱中,通过对12个不同钢纤维掺量与钢筋配置的试件进行轴压试验,系统研究了钢纤维体积率与配箍率对薄保护层CES短柱轴压性能与开裂行为的影响规律,并通过数值模拟和参数分析,提出了薄保护层CES柱的设计建议和极限承载力的简化计算公式。

试验设计

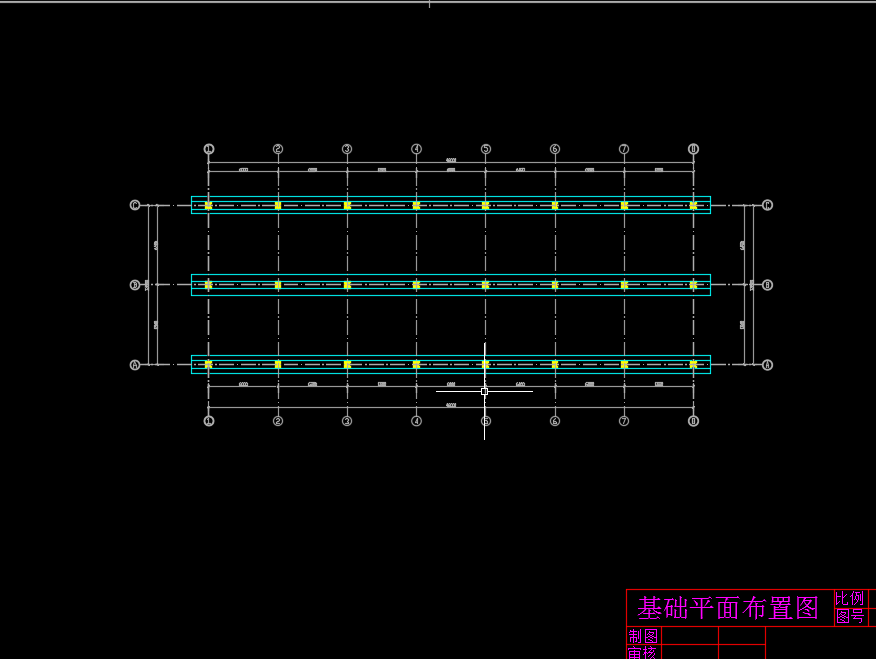

为系统研究钢纤维体积率与配筋形式对C-FHCES柱轴压性能及抗裂性能的影响,本研究共设计制作了13个试件,包括12根C-FHCES短柱及1根无纤维对照试件,具体设计参数如表1所示。试件配筋设计如图1所示:A型配置采用12根纵筋与封闭箍筋形成完整钢筋骨架;B型配置简化为4根角部纵筋与基础箍筋,以探究角部纵筋对破坏模式的影响;C型配置完全不配置钢筋,用于验证钢纤维替代传统钢筋约束的可行性。试件高度统一设为500 mm,以确保试验集中于材料强度与截面性能研究。型钢骨架采用8 mm厚腹板与12 mm厚翼缘焊接而成,含钢率为9.68%。所有钢筋直径均为8 mm,其中矩形箍筋由两个U形钢筋交叉焊接成型。

混凝土中掺入了长度为14 mm、直径为0.2 mm的微细钢纤维作为增强材料。材性试验结果显示,钢纤维体积率分别为0%、0.5%、1.0%和1.5%的混凝土,其平均立方体抗压强度依次为59.0 MPa、62.0 MPa、71.6 MPa和58.4 MPa。值得关注的是,当钢纤维体积率达到1.5%时,出现了明显的纤维结团现象,这一缺陷直接导致了混凝土强度的显著下降。钢纤维混凝土配合比如表2所示。

图1 C-FHCES柱设计方案(单位:mm) 表 1 试件设计参数 表 2钢纤维混凝土配合比

如图2(a)所示,轴压试验在北京工业大学工程试验中心完成,试验以按规范JGJ 138式(1)计算得到的组合截面名义承载力NJGJ为基准荷载,当荷载小于0.6NJGJ时按0.1NJGJ为级差加载,每级持荷5分钟;超过0.6NJGJ后改为每级0.05NJGJ,持荷8分钟,以便观测裂缝发展;当荷载降至峰值荷载的85%时终止试验。为确保荷载均匀传递,试件端部经角磨机打磨平整,并使用水平尺校验其与加载板的贴合度。裂缝观测采用图2(b)所示方法:当混凝土表面出现裂缝时,采用裂缝宽度计垂直于裂缝方向测量最大宽度,该仪器配备触觉探头扫描仪和LCD显示屏,测量精度为0.01 mm。

(a)试验加载装置与加载方案 (b)裂缝测量装置 图2 试件加载与裂缝测量装置

试验结果

对于未掺钢纤维的试件 X0-SF0-A-S100,由于高强混凝土的脆性较大且薄型钢保护层的约束作用有限,早期即出现明显的竖向裂缝,裂缝宽度迅速扩大。当荷载继续增加时,混凝土表面剥落加剧,箍筋屈服,外侧纵筋失去约束并发生屈曲。至极限荷载时,翼缘外侧混凝土被压碎并大面积剥落,型钢翼缘与腹板出现波浪形屈曲,纵筋屈曲明显。可见,混凝土保护层及箍筋的过早破坏显著削弱了核心混凝土与型钢的协同工作能力,使型钢在混凝土保护层失效后易发生局部屈曲。

掺入钢纤维并配置纵筋的 C-FHCES 系列试件的裂缝发展过程明显延缓。其混凝土表面裂缝数量减少、宽度增长缓慢,且多在高荷载阶段(约 0.7NJGJ 以上)才开始出现。钢纤维在裂缝形成后产生有效的桥接作用,阻止了裂缝贯通与混凝土剥落,使混凝土的抗压性能得以充分发挥。极限状态下,混凝土整体性保持良好,型钢与纵筋虽发生屈曲,但破坏过程平缓,延性显著提高。荷载下降至峰值的 85% 时,纵筋外侧混凝土出现翘曲破坏,表明外侧纵筋的屈曲对混凝土层产生一定的横向挤压作用。

对于仅掺钢纤维而未配置纵筋的 Type-C 系列试件,当钢纤维体积分数低于 1.5% 时,裂缝在较低荷载下即出现并迅速扩展,混凝土在轴压作用下产生膨胀并剥落,型钢未能充分发挥承载能力,整体抗压性能下降,破坏呈现明显的脆性特征。相比之下,掺钢纤维且配置纵筋的构件具有更高的抗裂性与变形能力,而仅掺钢纤维的构件约束作用不足,不宜单独采用。

综合试验结果可知,钢纤维的掺入能显著改善混凝土裂缝控制性能,增强核心混凝土与型钢的协同作用;而箍筋的设置进一步抑制了混凝土剥落与型钢屈曲,从而有效提升了构件的延性与承载力。相反,缺乏箍筋约束的钢纤维试件在高荷载作用下易发生脆性破坏,其强度与韧性均显著降低。

(a) 混凝土剥落和开裂情况 (b) Nu时混凝土破坏情况 (c) 85% Nu时的混凝土破坏情况 (d) 失效后型钢与钢筋破坏情况 图3.无纤维试件X0-SF0-A-S100的破坏特征 (a) Nu时混凝土破坏情况 (b) 85% Nu时的混凝土破坏情况 (c) 失效后型钢与钢筋破坏情况 图4.纤维试件X1-SF0.5-A-S100典型破坏特征 (a) Nu时混凝土破坏情况 (b) 85% Nu时的混凝土破坏情况 (c)失效后型钢与钢筋破坏情况 图5 试件的破坏模式图5.纤维试件破坏特征

图6(a)给出了C-FHCES柱的荷载-位移曲线。各试件在加载初期表现出相近的刚度,说明钢纤维体积分数与配筋形式对初始轴向刚度影响较小。未掺钢纤维的试件X0-SF0-A-S100由于薄保护层早期失效,混凝土抗压强度未能充分发挥,极限承载力明显低于其他试件,且刚度退化更早。掺钢纤维试件在加载过程中表现出良好的抗裂性能,钢纤维的桥接作用有效抑制了裂缝扩展,提高了混凝土的受压能力。相比之下,采用Type-C配筋形式的试件因约束不足,在达到峰值强度后迅速失稳破坏。图6(b)与图7的承载力与抗裂性能分析结果表明,掺入钢纤维能显著提高试件的极限承载力,其中1.0%钢纤维体积分数的增强效果最为显著。在该掺量下,试件不仅极限承载力最高,裂缝控制效果也最优。当钢纤维含量提高至1.5%时,混凝土内部出现纤维团聚与空隙,导致密实度下降,强度与抗裂性能反而有所减弱。

(a)荷载-位移曲线 (b)峰值承载力对比 图6. C-FHCES柱的轴压性能 (a)Ncrack-ρs (b)N0.3-ρs 图7. 抗裂能力对比

有限元分析

图8给出了基于Mander约束模型的有限元模型的网格划分、边界条件及构件组成(具体设计参数请见论文)。以 X7-SF1.0-B-S200 试件(钢纤维体积分数 1%、箍筋间距 200 mm、配筋形式为 B 型)为基准模型,开展参数化分析。主要考察翼缘厚度 、腹板厚度、型钢保护层厚度及相对长细比对轴压性能的影响。www.gc5.com

保持柱截面尺寸不变的条件下,增大翼缘与腹板厚度可使极限承载力略有提高,刚度呈线性增加趋势,但对材料强度利用率影响较小。如图9所示的接触应力分析表明,翼缘厚度对核心混凝土约束作用最为显著:当翼缘厚度由 10 mm 增加至 14 mm 时,PSCC 区域接触应力提升 67.3%,HSCC 区域提升 87.4%;腹板厚度影响相对较小。随着型钢保护层厚度增加,非约束混凝土区面积增大(图10)。结合工程可行性与规范要求,型钢保护层最小厚度取 45 mm。分析结果显示,在 45-55 mm 范围内,型钢保护层厚度对极限承载力和材料利用率影响较小,但能显著减小混凝土等效塑性应变范围,抑制表面开裂。综合考虑,建议型钢保护层厚度取55 mm。为考虑构件可能的屈曲效应,模型引入初始弯曲变形 H/1000作为初始缺陷。如图11所示,当相对长细比 >0.2时,柱及型钢的极限承载力明显下降,且中部横向位移迅速增大,表现出由强度破坏向失稳破坏的转变。

图8. C-FHCES柱有限元模型 图9. 混凝土与型钢间的接触应力云图 图10.不同型钢保护层厚度的 C-FHCES柱PEEQ云图 (a)峰值荷载 (b)最大水平位移 图11. 不同长细比下的FE结果

极限承载力计算方法

假设钢翼缘根部在极限荷载下发生局部弯曲屈服,将钢翼缘和腹板的约束分布可简化为均匀侧向约束应力(图12),HSCC与PSCC受到的有效约束应力可通过各自有效约束面积与总体约束面积的比值进行计算。此外,基于Mander和Sheikh的箍筋约束理论,十字型箍筋可简化为如图13所示的X、Y两个方向的矩形箍筋,箍筋对混凝土的约束通过叠加法计算。为保证设计保守,计算截面取在相邻箍筋中间位置,即约束作用最弱处。X、Y方向的有效约束应力由理论矩形箍筋模型得到。如图14所示将型钢与箍筋的有效约束应力在X、Y方向上叠加,得到HSCC与PSCC区域的均匀有效约束应力,并据此求得对应的混凝土约束强度增量系数KHSCC和KPSCC。

图12. 型钢约束应力简化模型 (十字截面的1/4). 图13. 箍筋简化有效约束区域 图14. 约束应力的线性叠加

钢纤维强度影响通过非线性回归得到钢纤维增强系数φsf的计算式,并基于Eurocode 4提出适合于C-FHCES柱的屈曲曲线(图15)。综合考虑钢翼缘与箍筋的约束作用、钢纤维对混凝土强度的提升及长细比影响,如式(2)-(6)提出C-FHCES柱的极限承载力计算公式。

图15. C-FHCES柱拟合柱子曲线

研究结论

(1) 钢纤维的引入能够有效延缓裂缝的产生与扩展。 掺入钢纤维后,混凝土的应变增长速率显著减缓,试件在达到极限荷载时仍能保持良好的整体性与结构完整性。

(2) 对于 C-FHCES柱,采用 45 mm 的型钢保护层厚度可有效防止混凝土的早期剥落及型钢局部屈曲的提前发生。掺钢纤维并配置纵筋的试件表现出较高的极限承载力和理想的破坏形态。综合分析推荐采用钢纤维体积分数1%、箍筋间距200 mm、配筋形式为B型的构造参数,以获得最佳的轴压与抗裂性能。

(3) 增大翼缘厚度可提高核心混凝土的约束效应,而增加型钢保护层厚度对抑制混凝土裂缝的产生与发展具有显著作用。

(4) 当 C-FHCES柱的相对长细比超过0.2 时,应考虑构件的整体稳定性影响。研究表明,适用于C-FHCES柱的屈曲曲线缺陷系数取值为 0.25。

(5) 综合考虑钢翼缘与箍筋对核心混凝土的约束作用、钢纤维的强度增强效应以及 长细比的稳定性影响,提出了一种 C-FHCES柱轴向极限承载力的计算模型,并通过试验结果对该模型进行了验证。

参考文献

[1] Dundar C, Tokgoz S, Tanrikulu AK, et al. Behaviour of reinforced and concrete-encased composite columns subjected to biaxial bending and axial load. Building and Environment, 2008, 43(6): 1109-1120.

[2] Liu XG, Xu CZ, Liu JP, et al. Research on special-shaped concrete-filled steel tubular columns under axial compression. Journal of Constructional Steel Research, 2018, 147: 203-223.

[3] Wang YY, Yang YL, Zhang SM, et al. Seismic behaviors of concrete-filled T-shaped steel tube columns. Key Engineering Materials, 2009, 400: 677-683.

[4] Xiong QQ, Chen ZH, Zhang W, et al. Compressive behaviour and design of L-shaped columns fabricated using concrete-filled steel tubes. Engineering Structures, 2017, 152: 758-770.

[5] Tu YQ, Shen YF, Li P. Behaviour of multi-cell composite T-shaped concrete-filled steel tubular columns under axial compression. Thin-Walled Structure, 2014, 85: 57-70.

[6] Zhang AL, Yu J, Xu M, et al. Experimental research on steel specially shaped columns with T-section under cyclic loading. Journal of Building Structures, 2010, 31(02): 20-28.

[7] Gautham A, Sahoo DR. Behavior of steel-reinforced composite concrete columns under combined axial and lateral cyclic loading. Journal of Building Engineering, 2021, 39: 102305.

[8] Mander JB, Priestley MJN, Park R. Theoretical stress-strain model for confined concrete. Journal of Structural Engineering, 1988, 114(8): 1804-1826.

[9] Zhao XZ, Wen FP, Chan TM, et al. Theoretical stress–strain model for concrete in steel-reinforced concrete columns. Journal of Structural Engineering,2019, 145(4): 04019009.

[10] Chen SW, Wu P. Analytical model for predicting axial compressive behavior of steel reinforced concrete column. Journal of Constructional Steel Research, 2017, 128: 649-660.

[11] Liu XC, Meng K, Chen XS, et al. Axial compression behavior of prefabricated L-section thin concrete encased steel short columns. Journal of Constructional Steel Research, 2023, 208: 107989.

[12] Li CH, Liu XC, Zhang AL, et al. Axial compressive behaviour of concrete encased extended I-shaped steel composite stub columns with less reinforcement. Engineering Structures, 2023, 287: 116167.

[13] Fang L, Zhang B, Jin GF, et al. Seismic behavior of concrete-encased steel cross-shaped columns. Journal of Constructional Steel Research, 2015, 109: 24-33.

[14] Lai BL, Liew JYR, Wang TY. Buckling behaviour of high strength concrete encased steel composite columns. Journal of Constructional Steel Research, 2019, 154: 27–42.

[15] Lai BL, Liew JYR, Venkateshwaran A, et al. Assessment of high-strength concrete encased steel composite columns subject to axial compression. Journal of Constructional Steel Research, 2020, 164: 105765.

[16] Lai BL, Liew JYR. Investigation on axial load-shorting behaviour of high strength concrete encased steel composite section. Engineering Structures, 2021, 227: 111401.

[17] Ellobody E, Young B. Investigation of concrete encased steel composite columns at elevated temperatures. Thin-Walled Structures, 2010, 48(8): 597-608.

[18] Liu X C, Meng K, Chen X, et al. Behavior of prefabricated cruciform thin concrete cover encased steel column under axial compression. Structures. 2024, 66: 106865.

[19] Liu X C, Liu Y K, Chen X, et al. Axial compression behavior of prefabricated cruciform-section thin-concrete-encased steel short column. Journal of Constructional Steel Research, 2024, 217: 108640.

[20] Venkateshwaran A, Lai BL, Liew JYR. Design of Steel Fiber-Reinforced High-Strength Concrete-Encased Steel Short Columns and Beams. ACI Structural Journal, 2021, 118(1): 45-59.

[21] Sun LL, Ma QJ, Han F, et al. Experimental investigation on axial compression behavior of steel reinforced concrete columns with welded stirrups. Engineering Structures, 2019, 208: 109924.

[22] Chang Y, Shi J, Hou Y, et al. Experimental study on the uniaxial compression performance of ultrahigh-performance concrete constrained by stirrups and fibers. Engineering Structures, 2021, 243: 112656.

[23] Yazıcı Ş, İnan G, Tabak V. Effect of aspect ratio and volume fraction of steel fiber on the mechanical properties of SFRC. Construction and Building Materials, 2007, 21(6): 1250–1253.

[24] Xie TY, Ozbakkaloglu T. Behavior of steel fiber-reinforced high-strength concrete-filled FRP tube columns under axial compression. Engineering Structures, 2015, 90: 158-171.

[25] Gao D, Li W, Pang Y, et al. Behavior analysis and strength prediction of steel fiber reinforced recycled aggregate concrete column under axial compression. Construction and Building Materials, 2021, 290: 123278.

[26] Khaloo A, Raisi E M, Hosseini P, et al. Mechanical performance of self-compacting concrete reinforced with steel fibers. Construction and Building Materials, 2014, 51: 179-186.

[27] GB/T 50152-2012, Standard for Test Method of Concrete Structures. Beijing: China Architecture & Building Press, 2012. [in Chinese].

[28] GB/T 228.1-2021, Metallic Materials-Tensile Testing- Part1: Method of Test at Room Temperature. Beijing: China Standards Press, Beijing, 2021. [in Chinese].

[29] JGJ 138-2016, Code for design of composite structures. Beijing: China Architecture & Building Press, 2016. [in Chinese].

[30] GB/T 50010-2010, Code for design of concrete structures. Beijing: China Architecture & Building Press, Beijing, 2010. [in Chinese].

[31] Park R. Ductility evaluation from laboratory and analytical testing. Proceedings of the 9th World Conference on Earthquake Engineering, 1988, 8: 605-616.

[32] Fang Q, Zhang JH. Three-dimensional modelling of steel fiber reinforced concrete material under intense dynamic loading. Construction and Building Materials, 2013, 44: 118-32.

[33] Zhang SL, Zhang CS, Liao L, et al. Investigation into the effect of fibre distribution on the post-cracking tensile strength of SFRC through physical experimentation and numerical simulation. Construction and Building Materials, 2020, 248: 118433.

[34] Rezakhni R, Scott DA, Bousikhane F, et al. Influence of steel fiber size, shape, and strength on the quasi-static properties of ultra-high performance concrete: Experimental investigation and numerical modeling. Construction and Building Materials, 2021, 296: 123532.

[35] Abdallah S, Fan M, Rees DWA. Analysis and modelling of mechanical anchorage of 4D/5D hooked end steel fibres. Materials & Design, 2016, 112: 539-52.

[36] Ellobody E, Young B. Design and behaviour of concrete-filled cold-formed stainless steel tube columns. Engineering Structures, 2006, 28(5): 716-728.

[37] Ellobody E, Young B. Nonlinear analysis of concrete-filled steel SHS and RHS columns. Thin-Walled Structures, 2006, 44(8): 919–930.

[38] El-Tawil SM, Deierlein GG. Fiber element analysis of composite beam-column cross-sections. New York: Cornell University, 1996.

[39] Sheikh SA, Uzumeri SM. Strength and ductility of tied concrete columns. Journal of the Structural Division, 1980, 106(5): 1079-1102.

[40] Sheikh SA, Uzumeri SM. Analytical model for concrete confinement in tied columns. Journal of the Structural Division, 1982, 108(12): 2703-2722.

[41] EN 1992-1-1, Eurocode 2: Design of Concrete Structures. Part 1-1: General Rules and Rules for Buildings. Brussels: CEN, 2004.

[42] ACI 318-25, Building code requirements for structural concrete and commentary. Farmington Hills: American Concrete Institute, 2025.

[43] EN 1994-1-1, Eurocode 4: Design of composite Steel and Concrete Structures. Part 1-1: General Rules and Rules for Buildings. Brussels: CEN, 2004.

[44] Shi G, Zhang ZQ, Zhou L, et al. Experimental and numerical investigation on local-overall interactive buckling behavior of welded I-section steel columns. Thin-Walled Structures, 2020, 151: 106763.

[45] Dar MA, Sahoo DR, Jain AK. Influence of chord compactness and slenderness on axial compression behavior of built-up battened CFS columns. Journal of Building Engineering, 2020, 32: 101743.

[46] Song PS, Hwang S. Mechanical properties of high-strength steel fiber-reinforced concrete. Construction and Building Materials, 2004, 18(9): 669-673.

[47] Abbass W, Khan MI, Mourad S. Evaluation of mechanical properties of steel fiber reinforced concrete with different strengths of concrete. Construction and Building Materials, 2018, 168: 556-569.